Our Services regarding "permeation"

permeation, leak tightness, barrier properties

We measure the permeation of gases or water vapor through films, coated paper and fabric, containers, bottles, bags or packing components under a variety of climatic conditions.By many special measurements for the evaluation of packaging components such as welding spouts, valves, opening assistance, laser perforations and valves regarding tightness and permeation behavior we could gain in the last years a broad wealth of experience. Basic studies for the investigation of the influence of thermal treatments and other stress conditions on barrier and tightness of packing materials round our field of activity off. Talk to us, we will gladly advise you in selecting the optimal test conditions for your task.Innoform advises you on the selection of the optimum permeation test conditions

Permeation, leak tightness, barrier properties

At Innoform we measure the permeation of gases or water vapour through films, coated papers and fabrics, containers, bottles, bags or packaging components under a wide range of climatic conditions. Through many special measurements for the evaluation of packaging components, such as shrink-wrapped parts, opening aids, laser perforations and valves with regard to tightness and permeation behaviour, we have been able to acquire a wealth of experience in recent years. Basic research on the influence of heat treatment and other stress conditions on the barrier and tightness of packaging materials round off our field of activity. Please contact us, we will be pleased to advise you on the selection of the optimum test conditions for your task.

Tightness of packaging: What a permeation test is needed for

In the following, we would like to briefly explain how our tests are of increased relevance with regard to the tightness of packaging, for example with regard to the shelf life of food. First of all, some basic information about the process of permeation: in a first step, the foreign molecule is absorbed on the surface of the material, then the diffusion of the molecule through the matter takes place, and finally the molecule is desorbed on the other side of the material. This mechanism is crucial for the speed of permeation. Accordingly, the permeation coefficient P is formed from the product of the diffusion coefficient D and the solubility coefficient S. With the help of a permeation coefficient test, statements can finally be made about the tightness of a package.

Innform Permeation Analysis: We offer these permeation tests

At Innoform, we can use a permeation test to determine the permeation coefficient of a wide variety of substances, whether nitrogen, water vapour, carbon dioxide or oxygen. For example, the oxygen permeation of films, laminates, coated papers and aluminium composite films is tested as follows:

- Standard test in a normal room climate (23° C and 50 % relative humidity).

- Humidity test for packaging materials of products containing a lot of moisture (23° C and 75 % relative humidity)

- Special climate based on actual storage conditions

- Test under dry conditions, e.g. for dry filling goods (23° C and 0 % relative humidity)

The oxygen transmission rate (OTR) for the tightness of packaging, bags, moulded parts, bottles etc. is tested in the following tests:

- Standard test during storage under normal room conditions (23° C and 50 % relative humidity)

- Test under refrigerator conditions (5° C and 50 % relative humidity)

- Test under tropical climate conditions (38° C inside/50 % relative humidity inside and 85 % outside)

For the carbon dioxide permeation test, a manometric method is used in the same way as for the nitrogen permeation test. In order to test the water vapour transmission rate (WVTR), two different permeation methods are used in most cases:

- Test under the standard conditions prevailing in Europe (23° C and 85% relative humidity).

- Test under the standard conditions prevailing in a tropical climate (38° C and 90 % relative humidity)

An initial overview - the permeation calculator from Innoform

Once you have obtained the permeation coefficient of your material through the permeation check thanks to the competent team of experts, you can develop or adapt the materials of your product accordingly on the basis of this to enable complete or partial elimination of permeation. You don't have time to wait for the test results of the Innoform permeation analysis? No problem. You can already get a first overview of the tightness of your packaging thanks to our Innoform flashover permeation calculator. Do not hesitate to contact us if you have further questions regarding the permeation calculator and the right test procedure to check the tightness of your packaging or if you need even more information on the subject of permeation.

Search examinations

Your contact person

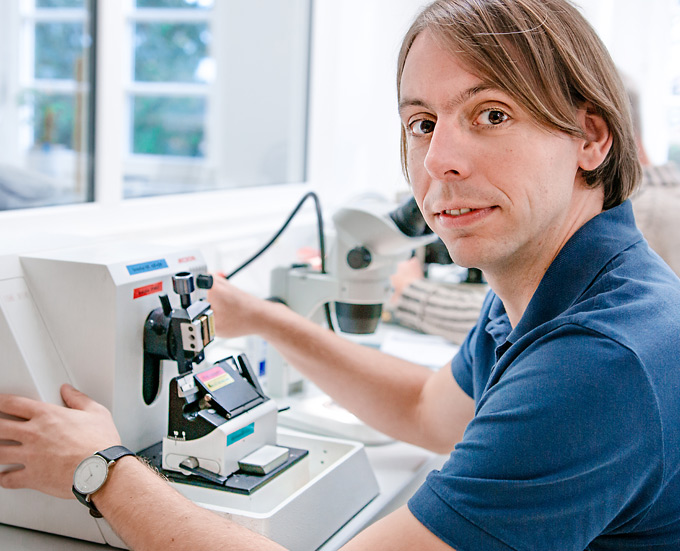

Matthias Böhne

Matthias Böhne

Examinations in this area

- Carbondioxyde transmission (CO2 TR) rate of plastic films, laminates, coated papers, Alufoils, etc.

- Determination of (residual) oxygen and carbon dioxide content in ready-made packages

- Nitrogen transmission rate (N2 TR) of plastic films, laminates, coated papers, alufoils etc.

- Oxygen transmission rate (OTR) of packages, pouches, moulded parts, bottles, etc. (only suitable for barrier materials, see also "i")

- Oxygen transmission rate (OTR) of plastic films, laminates, coated papers, Alufoils, etc.

- Permeation (air, helium, argon, others on request) of plastic films, laminates, coated papers, Alufoils

- Tightness, leakage test/pores/micro-holes/defects

- Water Vapour Transmission Rate (WVTR) of moulded parts, packages, pouches, bottles, etc. (only suitable for barrier materials, see also "i")

- Water vapour transmission rate (WVTR) plastic films, laminates, coated papers and aluminium foils

- Water vapour transmission rate (WVTR), gravimetric test

- Water vapour transmission rate (WVTR)/ Sd- value (water vapour diffusion-equivalent air layer thickness)